IMPRS for Advanced Methods in Process and Systems Engineering

Since 2007, we investigate challenging problems of process and systems engineering, characterized both by high complexity and high practical relevance. For this purpose, advanced theoretical methods and tools, provided by systems theory and systems engineering, are combined closely with powerful experimental methods and techniques. The school’s funding will end in August 2025.

Our research focus

Systems theory, well-designed experiments and efficient harvesting of wet lab data for modelling purposes are the core pillars of our graduate school.

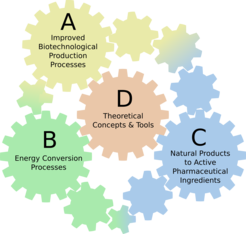

This conceptual framework is made concrete by our four research clusters:

- A: Improved biotechnological production of biologicals, chemicals and biopolymers,

- B: Efficient energy conversion processes based on renewables,

- C: From natural products to active pharmaceutical ingredients,

- D: Methods and tools.

Some research groups which are in advanced research phases do not accept new PhD students. More information:

Cluster A: Improved biotechnological production of biologicals, chemicals and biopolymers

Biotechnological production processes are becoming more and more important not only for the production of biologicals including vaccines and recombinant proteins, but also for the sustainable production of platform chemicals and biopolymers. Major challenges, in view of economic attractiveness and competitiveness with established traditional processes and products, are the increase of the product yields, flexible adjustment of the desired product quality and product safety. Within the IMPRS, new concepts and new methods are being developed for this purpose.

Main topics:

- computational strain design and new design principles including the coupling of growth and product formation, tailor-made microbial communities, and dynamic metabolic engineering;

- dynamic modelling and process control under uncertainty with application to the production of biopolymers with tailor-made properties; and

- cell culture-based production of viral vaccines and recombinant proteins with special focus on cellular heterogeneity, influence of flow fields in systems with high cell density, and the influence of cellular resources on productivity.

Principal investigators:

- Dr. Katja Bettenbrock: Analysis and Redesign of Biological Networks/ Systems Biology

- Prof. Achim Kienle: Automation/Modelling

- Dr. Steffen Klamt: Analysis and Redesign of Biological Networks

- Prof. Udo Reichl: Bioprocess Engineering

- Prof. Dominique Thévenin: Fluid Dynamics and Technical Flows

Cluster B: Efficient energy conversion processes based on renewables

The realization of a defossilized energy supply system requires the efficient storage of volatile electrical energy harvested from renewable sources (wind/solar). Very efficient energy storage is achievable by conversion of electrical energy particularly into hydrogen generated by water electrolysis. Due to the missing hydrogen infrastructure, it is advantageous directly converting hydrogen via hydrogenation of CO2 into other substances, which are easier to store and to distribute, particularly methane, methanol, dimethyl ether and Fischer-Tropsch fuels. The volatility of electrical energy from renewables will lead to a fluctuating supply of hydrogen. For avoiding large-scale hydrogen buffer tanks, it would be desirable to perform the CO2 hydrogenation reactions in catalytic reactors able to cope with dynamically changing feed streams. Conventional catalysts, reactors and electrolysis processes had been developed for operation at steady state conditions. Little is known so far about the design principles of stable porous catalyst systems and dynamically operating catalytic reactors and electrolyzers able to withstand temporal changes of gas composition, temperature and pressure. A consistent analysis of the dynamics, covering the reaction and transport processes on all time and length scales involved, is largely missing. The IMPRS topical cluster B focuses on different research opportunities within the just sketched energy system scenario.

Main topics:

- modelling, simulation and optimization of complex chemical energy conversion networks;

- detailed analysis of reaction and transport phenomena in water electrolysis processes;

- multiscale analysis of catalytic conversion processes; and

- dynamic storage and reuse of heat released during chemical energy conversion.

Principal investigators:

- Prof. Dr. Franziska Scheffler: Technical Chemistry

- Dr. Matthias Stein: Molecular Simulations and Design

- Prof. Dr.-Ing. Kai Sundmacher: Process Systems Engineering

- Prof. Dr.-Ing. Evangelos Tsotsas: Thermal Process Engineering

- Dr.-Ing. Tanja Vidakovic-Koch: Electrochemical Energy Conversion

Cluster C: From natural products to active pharmaceutical ingredients

In the last years, remarkable progress has been achieved worldwide in designing, optimizing and implementing selective separation processes capable to isolate and purify value added products present in complex mixtures. Relevant methods, which have been in investigated in Magdeburg, are chromatography and crystallization. These methods were more recently also applied to purify extracts obtained from natural products. As an example, various extracts of Artemisua annua containing artemisinin, an efficient anti-malaria drug, are studied in the IMPRS. Frequently, due to the exploitation of less suitable solvents and the low degree of predicting the outcome of the extraction processes, there are still large losses in this important initial stage of providing valuable target molecules.

In order to develop improved approaches for the whole process chain of isolating valuable target molecules from natural products, main topics are:

- rational solvent selection,

- solid-liquid counter-current extraction processes,

- analyzing options for combining continuously carried out extraction and separation processes,

- considering to exploit waste components, and

- optimization of the whole process chain.

Principal investigators:

- apl. Prof. Dr. Heike Lorenz: Physical and Chemical Foundations of Process Engineering/ Selective Crystallization

- Prof. Andreas Seidel-Morgenstern: Physical and Chemical Foundations of Process Engineering

Cluster D: Methods and tools

The last decade has seen an immense emergence of several new aspects in the computational sciences and engineering. This includes in particular the stochastic modeling of uncertainties in physical, chemical, biological processes and engineering problems, the related quantification of uncertainties (UQ), as well as the coupling of data and models in order to achieve better predictive capacities than possible with models that are solely derived from first principles or phenomenologically. This leads to a number of challenging computational tasks, in particular if the model description is obtained via partial differential equations. Many of these challenges relate in one way or the other to Bellman’s curse of dimensionality, so that the pure advance in computing power will not suffice to apply these modeling principles to next generation engineering processes. New algorithmic developments are required here, that deal with the multi-dimensionality of problems obtained after discretizing the uncertain parameters etc. Concepts able to cope with this need to exploit intrinsic structures, for which both, mathematical and engineering insight, are required. We develop such novel, efficient algorithms that are able to master the challenges for the numerical modeling and simulation of the processes investigated in areas A)-C).

Main topics:

- low-rank (matrix and tensor) techniques for (Bayesian) statistical inversion of nonlinear problems,

- algorithms for decision-making under uncertainty,

- deriving optimal and feedback controllers for chemical and biological processes under uncertainty,

- identification of nonlinear models from data,

- co-simulation of models consisting of partial differential equations and partial models identified from data.

Principal investigators:

- Prof. Peter Benner: Computational Methods in Systems and Control Theory

- Dr. Lihong Feng: Computational Methods in Systems and Control Theory/ Model Order Reduction

- PD Dr. Gabor Janiga: Fluid Dynamics and Technical Flows

- Dr. Feliks Nüske: Data-driven Modeling of Complex Physical Systems

- Prof. Sebastian Sager: Mathematical Algorithmic Optimization

- Prof. Thomas Richter: Numerical Mathematics with Applications

Research groups in advanced research phases (no new students accepted)

- Prof. Rolf Findeisen: Systems Theory and Automatic Control

- Prof. Ulrike Krewer: Energy and Process Systems Engineering

- Prof. Wolfgang Marwan: Regulatory Biology

- Prof. Martin Stoll: Numerical Linear Algebra for Dynamical Systems

- Prof. Gerald Warnecke: Numerical Mathematics

Former research groups of the IMPRS

- Prof. Dietrich Flockerzi: Mathematical Foundation of Dynamical Systems

- Jun.-Prof. Marcus Hauser: Institute for Experimental Physics

- Prof. Volker Kaibel: Discrete Optimization

- Dr. Jörg Schaber: Institute for Experimental Internal Medicine

- Prof. Steffen Waldherr: Theory of Complex Networks

- Prof. Robert Weismantel: Discrete Optimization