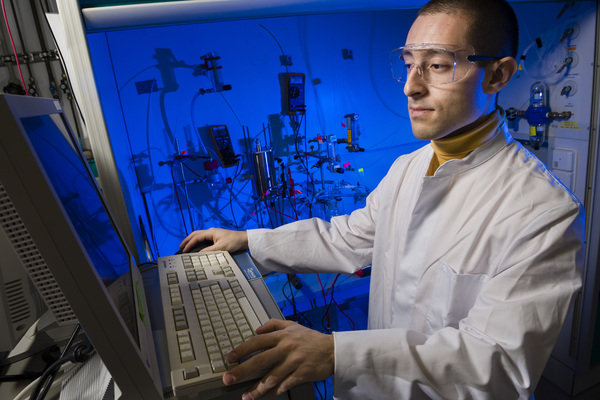

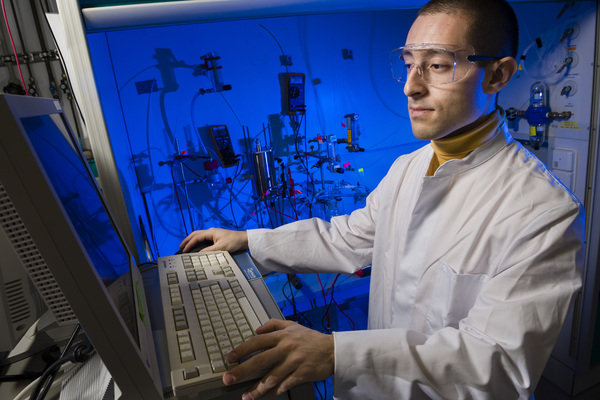

The CatSys project focuses on the optimal design of processes for the production of commodity chemicals such as Cl

2, HCN and NH

3 by (electro-) catalytic gas phase reactions at low energy consumption, utilizing a close combination of mathematical modeling with experimental data at different process levels. Thereby, the PSE group has strong interactions with national and international research groups (Prof. T. Turek, Technical University Clausthal, Prof. M.R. Singh, University of Illinois at Chicago, Dr. A.Z. Weber, Berkeley National Laboratory) and leading chemical companies such as Evonik and Covestro. As an example, a novel electrochemical gas phase HCl oxidation process is briefly presented herein.