DynElectro: Dynamic Hydrogen Production by Water Electrolysis

Within the Power-to-X context, in the project DynElectro we focus on PEM water electrolysis, a promising technology for hydrogen production due to high current densities and the ability to respond quickly to dynamic power fluctuations. We are interested in understanding the essential degradation mechanisms, which influence the aging of the electrolyzer under different operating conditions. To be able to cope with the high complexity of the many intercoupled processes in the electrolytic cell, we rely on the combination of experimental investigation with mathematical modeling and simulation. The gained process understanding can be used to improve practical applications and mathematical models can serve as a basis for life time estimation and numerical optimization.

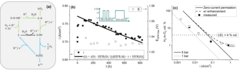

A particular focus of our research is targeted at Iridium catalyst degradation on the anode side, accounting for the low catalyst loadings needed for the scale-up of the PEM technology due to the scarcity of noble metals such as Iridium. On the half-cell level, we investigate fundamental reaction mechanisms of the Oxygen Evolution Reaction (OER) and the associated catalyst corrosion (Fig. 1a) [1]. On the single cell level, we explore how these mechanisms affect real-world electrolysis under dynamic operation conditions (Fig. 1b) [2]. The mechanisms of water transport play a crucial role for performance and degradation [3]. Hydrogen permeation to the anode side is important not only with regard to operational safety, but it also has an important influence on catalyst aging (Fig. 1c) [4].

We directly apply our model-based knowledge about the behavior of PEM water electrolysis in the region project “Energieregion Staßfurt”, for which we work on the dynamic modeling and simulation of a complete electrolysis system, including all components within the balance of plant. In the same context of transitioning to a carbon-free, hydrogen-based energy system, we currently develop a superstructure optimization approach for supporting the identification of the best overall system design, including gas and electricity distribution networks, site selection for electrolyzers and H2 filling stations, as well as power-to-methane components to be fed with CO2 from biogas plants.

Publications

[1] Dam, A., D., Papakonstantinou, G., Sundmacher, K. (2020) Sci. Rep., 10:14140

[2] Papakonstantinou, G., Algara-Siller, G., Teschner, D., Vidakovic-Koch, T., Schlögl, R., Sundmacher, K. (2020), Appl. Energy, 280, 115911

[3] Zinser, A., Papakonstantinou, G., Sundmacher, K. (2019), Int. J. Hydrogen Energy, 44, 28077

[4] Papakonstantinou, G., Sundmacher, K., (2019) Electrochem. Comm., 107, 106778