Control of Particulate Processes

Approaches and results

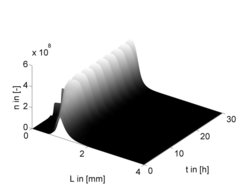

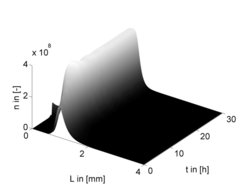

As particulate processes are typically modeled by population balance equations, i.e. nonlinear integro-differential equations, control design is a challenging issue. Suitable approaches developed in the PSD group can be categorized into two classes:

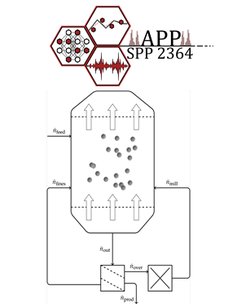

- Early lumping. Here, the model of the particulate process is lumped applying appropriate discretization schemes. In order to cope with the introduced errors and other model uncertainties robust control methods are applied. [6,7,11,13,15,16]

- Late or no lumping. Applying a generalized stability concept, i.e. stability with respect to two discrepancies, a nonlinear control law can be derived without any model reduction [4,14,17]. In order to account for model uncertainties and time-varying process behavior the discrepancy based control approach can be extended by appropriate adaptation schemes [12]. In addition to the aforementioned discrepancy based control two different control approaches have been developed and investigated for two specific granulation processes: model-free adaptive control based on a discrepancy [2] and control based on thermodynamic quantities [10] guaranteeing closed-loop stability in a classical sense, i.e. in terms of a L2-norm.

Although, population balance models are able to reflect the qualitative process behavior in many applications, modeling errors may be significant. The main two causes are a process specific time-variation of parameters and the deviation between process kinetics and kinetics identified from individual and simplified experiments. In order to overcome this problem a Lyapunov based identification scheme has been developed being able to identify population balance parameters and kinetics online in parallel to the process operation [1,3,9].

Cooperation

- Prof. Stefan Heinrich, Technische Universität Hamburg-Harburg

- Prof. Seidel-Morgenstern, Max-Planck-Institut Magdeburg

- Prof. Evangelos Tsotsas, Universität Magdeburg

- Prof. Richard Braatz, Massachusetts Institute of Technology

- Prof. Andreas Bück, Universität Erlangen

References

[1] I. Golovin, G. Strenzke, M. Wegner, S. Palis, A. Bück, A. Kienle, and E. Tsotsas. Parameter identification for continuous fluidized bed spray agglomeration, 2018. Paper presented at PBM 2018 in Ghent/Belgium.

[2] S. Palis. Non-identifier-based adaptive control of continuous fluidized bed spray granulation. Journal of process control, 71:46-51, 2018.

[3] S. Palis and A. Kienle. Online parameter identification for continuous fluidized bed spray granulation with external sieve-mill cycle. In 22nd Int. Conf. on Methods and Models, Miedzyzdrojie Pl, p. 594–598, 2017.

[4] R. Geyyer, R. Dürr, E. Temmel, T. Li, H. Lorenz, S. Palis, A. Seidel-Morgenstern, and A. Kienle. Control of continuous mixed solution mixed product removal crystallization processes. Chem. Eng. Technol., 40:1362–1369, 2017.

[5] A. Kienle, S. Palis, M. Mangold, and R. Dürr. Modeling and simulation of particulate processes. Electronic Modeling, ISSN 0204-3572, 38(5):23–33, 2016.

[6] S. Palis, C. Neugebauer, A. Bück, S. Heinrich, E. Tsotsas, and A. Kienle. Control of multi-chamber continuous fluidized bed spray granulation, 2016. PARTEC 2016: International Congress on Particle Technology, Nuremberg, Germany, April 19-21.

[7] R. Geyyer, S. Palis, and A. Kienle. Robust control of continuous crystallization processes. In Proc. 1st IFAC Conference on Modeling, Identification, and Control of Nonlinear Systems, Petersburg, June 24-26, 2015. IFAC-Papers-Online, Volume 48, Issue 11, p. 798-603.

[8] S. Palis & C. Dreyschultze & C. Neugebauer & A. Kienle. Auto-tuning control systems for improved operation of continuous fluidized bed spray granulation processes with external product classification. In: Procedia engineering. - Amsterdam [u.a.] : Elsevier, Bd. 102. 2015, pp. 102-133.

[9] S. Palis & R. Dürr & A. Kienle. Online parameter identification of facet growth kinetics in crystal morphology population balance models. In: Procedia engineering. - Amsterdam [u.a.] : Elsevier, Bd. 102. 2015, pp. 1336-1345.

[10] S. Palis, A. Bück, and A. Kienle. Entropy based control of continuous fluidized bed spray granulation processes. In Proc. 5th IFAC Workshop on Lagrangian and Hamiltonian Methods for Nonlinear Control, Lyon, July 4-7, 2015. IFAC-PapersOnline, Volume 48, Issue 13, p. 154-157.

[11] R. Geyyer & A. Kienle & S. Palis, Robust control of continuous crystallization processes, 1st IFAC Conference on Modelling, Identification and Control of Nonlinear Systems - MICNON (St. Petersburg), 2015.

[12] S. Palis, Adaptive discrepancy based control of particulate processes, 1st IFAC Conference on Modelling, Identification and Control of Nonlinear Systems - MICNON (St. Petersburg), 2015.

[13] A. Bück & S. Palis & E. Tsotsas, Model-based control of particle properties in fluidised bed spray granulation, Powder Technology, 2015, pp. 575–583.

[14] S. Palis & A. Kienle, Discrepancy based control of particulate processes, Journal of Process Control 24, 2014, pp. 33-46.

[15] S. Palis & A. Kienle, H infinity Loop Shaping Control for Continuous Fluidized Bed Spray Granulation with Internal Product Classification, Ind. & Eng. Chem. Research, 2013, pp. 408-420.

[16] S. Palis, A. Kienle, Stabilization of continuous fluidized bed spray granulation with external product classification, Chemical Engineering Science 70:200-209, 2012.

[17] S. Palis, A. Kienle, Diskrepanzbasierte Regelung der kontinuierlichen Flüssigkristallisation, at- Automatisierungstechnik 60, 2012, pp.145-154.