Monitoring and Control of High-Density Cell Culture Systems

Motivation

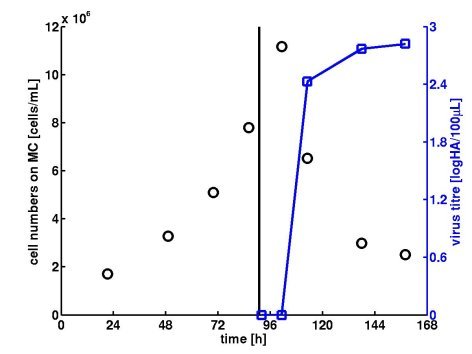

An obvious approach to optimize yields in vaccine manufacturing is the increase in cell concentration before infecting the cultures [1]. However, due to media limitations, accumulation of inhibitors and mass transfer limits cell specific virus productivity is often reduced in high-density cell cultures, the so-called 'cell density effect'.

Aims of the project

Design and optimization of high-density cell culture systems for influenza virus production. Monitoring of critical state and process variables to characterize cell growth and virus replication dynamics. Establishment of mathematical models for control of cultivation conditions to increase process productivity.

High-density cell culture

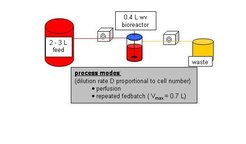

Medium exchange via perfusion or repeated fed-batch

Process monitoring and simulation

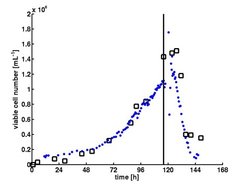

Estimation of viable cell number using oxygen uptake rates [2]

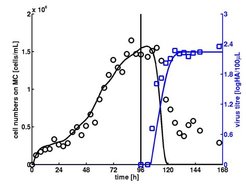

Simulation of viable cell number and virus titres using unstructured,

segregated mathematical models [3], [4]

Outlook

Results of model simulations and experimental data clearly suggest that cultivations with cell numbers of about 20 x 106 (1/mL) and more are feasible. To overcome limitations during cell growth and virus replication concepts for control of medium exchange should be applied [5]. Online estimation of cell numbers using oxygen transfer rates should allow determination of optimal time point of infection.

References

[1] Möhler L, Flockerzi D, Sann H and Reichl U. 2005. A Mathematical Model of Influenza A Virus Production in Large-Scale Microcarrier Culture. Biotechnology and Bioengineering (90)1:46-58

[2] Bock A, Reichl U. Monitoring of cell activity: online oxygen uptake rates in pulsed aerated cell culture. In: Noll T, editor. 20th meeting of ESACT; 2007; Dresden, Germany: Springer; 2007.

[3] Möhler L, Bock A, Reichl U. Segregated mathematical model for growth of anchorage-dependent MDCK cells in microcarrier culture. Biotechnology Progress 2008 ;24(1):110-9.

[4] Bock A, Möhler L, Sann H, Schulze-Horsel J, Genzel Y, Reichl U. Growth behaviour of number distributed adherent MDCK cells for optimization in large scale microcarrier cultures. Biotechnology Progress 2009, 25(6): 1717-1731

[5] Bock A, Schulze-Horsel J, Schwarzer J, Rapp E, Genzel Y, Reichl U.High-Density Microcarrier Cell Cultures for Influenza Virus Production. Biotechnology Progress 2011, 27(1): 241-250

Related projects

Monitoring, Design and Optimization of Bioprocesses

Influenza Vaccine Production in Microcarrier Systems and Suspension Cells

Flow Cytometric Analysis of Virus-induced Apoptosis and Virus Replication