Production of oncolytic viruses in suspension cultures

Oncolytic viruses (OVs) offer an elegant multimodal approach to cancer therapy through their ability to cause direct tumor cell lysis, while stimulating immune responses directed against the tumor. Nevertheless, the potential of OVs as monotherapeutics is limited by the relatively rapid onset of antiviral immune responses and insufficient adoptive immune stimulation to provide systemic tumor clearance and protection from relapse. Over the last decade, significant progress has been made in the development of enhanced OV therapies, and a variety of vectors have entered clinical trials [1-4].

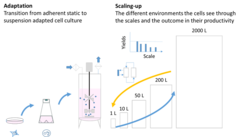

Established approaches to use adherent cells for oncolytic virus prodcution pose major challenges for large-scale production. Limited monitoring of pH, dissolved oxygen (DO), restricted harvesting options, and limited control of cultivation parameters such as feeding rates, complicate up-scaling for static anchorage-dependent cells. In comparison, the use of suspension cells allows for an easier scale-up from lab bench systems to large-scale industrial bioreactors.

Jennifer Altomonte (along with co-inventor, Oliver Ebert) has previously engineered a novel hybrid oncolytic virus technology, which combines the beneficial features of oncolytic vesicular stomatitis virus (VSV) with those of Newcastle disease virus (NDV), while eliminating the safety concerns of each [5]. This enhanced virus, named VSV-NDV, offers several beneficial features, including rapid and efficient tumor cell oncolysis generated by the induction of cell-cell fusion reactions, while maintaining an exceptional safety profile. Not only do the infected cells fuse with neighboring tumor cells, thereby killing them, but this process also sets off a series of events which causes beneficial modulation of the tumor microenvironment and activates the recipient’s immune system to launch an attack on remaining uninfected tumor cells throughout the body. Since VSV-NDV can replicate well in a multitude of tumor cells, it is expected to have far-reaching therapeutic effects in a broad range of tumor indications. Although VSV-NDV is effective as is, it offers a promising platform for combination with other immunotherapeutic strategies, as well as having the possibility to further arm the vector with therapeutic genes.

Moreover, together with Valneva as partner the use of their avian stem cell based EB66 suspension cells for the production of an oncolytic NDV virus in an intensified process is evaluated.

Aim of the project

- Overcome limitations of current anchorage-dependent cell-based manufacturing processes

- Development of a virus production platform, ideally transferrable to a wide range of oncolytic viruses

- Process intensification and control of high-cell density perfusion cultivations for a GMP-compliant production process

- Development and integration of a complete downstream process for oncolytic viruses

Publications

References

[1] Kirn, D., Martuza, R.L., and Zwiebel, J., Replication-selective virotherapy for cancer: biological principles, risk management, and future directions. Nat Med, 2001. 7: p. 781-7.

[2] Everts, B. and H.G. van der Poel, Replication-selective oncolytic viruses in the treatment of cancer. Cancer Gene Ther, 2005. 12(2): p. 141-61.

[3] Patel, M.R. and R.A. Kratzke, Oncolytic virus therapy for cancer: the first wave of translational clinical trials. Transl Res, 2013. 161(4): p. 355-64.

[4] Conry, R.M., et al., Talimogene laherparepvec: First in class oncolytic virotherapy. Hum Vaccin Immunother, 2018. 14(4): p. 839-846.

[5] Abdullahi, S., et al., A Novel Chimeric Oncolytic Virus Vector for Improved Safety and Efficacy as a Platform for the Treatment of Hepatocellular Carcinoma. J Virol, 2018. 92(23).