Production of tailor-made PHA biopolymers

Polyhydroxyalkanoates (PHAs) are a promising class of biopolymers. They are biodegradable and are produced by many microorganisms under unbalanced growth conditions (nitrogen, phosphate or oxygen limitations) as an internal carbon storage. About 10 years ago we conducted some research in the field with polyhydroxybutyrate (PHB) formation with fructose [R17] and glucose [R18] substrates in Ralstonia eutropha under nitrogen limitation. The emphasis was on mathematical modeling, nonlinear dynamics and some surprising experimental observations concerning glucose uptake of the wild type [R18].

Recently, we started a new project with the Findeisen group from OVGU/TU Darmstadt and partners from the Universities of Applied Sciences in Merseburg and Köthen. The main objectives are to reduce the cost of PHA production by using waste streams from the local food industry and to increase the biopolymer yield and quality by model-based control. The PSD group focuses on advanced modeling strategies, to account for additional substrates in the feed and how they affect biopolymer yield and properties. The effect on biopolymer properties is mainly due to the formation of co-polymers and varying chain length distributions.

with fructose and propionate substrate.

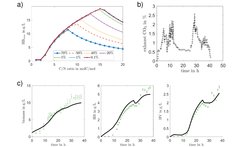

In a first step, our previous hybrid cybernetic model (HCM) was expanded by including acetate, a component frequently occurring in the waste streams, as an additional substrate [1]. It was possible to further improve the quality of the model by including the dependence on the dissolved oxygen (DO) levels in the process model [2]. By coupling this process variable to the biomass growth, it is possible to investigate the influence of the dissolved oxygen (DO) level applying different initial carbon/ammonium (C/N) ratios (Fig. 1a). This in silico investigation allows the following conclusion: the lower the DO, the lower the initial starting ammonium concentration required to obtain the maximum yield of biopolymer.

In addition to the model-based analysis of the PHB process with fructose and acetates as carbon sources, we also included propionate as an additional carbon source. With propionate it is possible to produce the biocopolymer poly(hydroxybutyrate-cohydroxyvalerate) PHBV, which is characterized by more advantageous properties compared to PHB, e.g., a lower melting temperature, lower Young’s module and increased elongation-to-break values [R19]. Since propionate has an inhibitory effect on cell growth, this substrate was added via pH-dependent regulation [R20]. The process was modeled using an advanced kinetic approach [3]. It relies on the measured CO2 profile of the process (Fig. 1b), and allows an accurate description of the process dynamics with moderate effort, as illustrated in Fig. 1c. Due to the required measurement information, the model is suitable for online estimation and control of the current PHBV composition and yield. Future work will deal with the regulation of autogenous CO2 and the coupling of the model approaches with detailed polymerization kinetics to better predict polymer product properties. First steps in this direction were undertaken in [4].

In collaboration with the Findeisen group also first model-based measurement [5] and control strategies [6] were developed for PHB.

Cooperation partners

- Prof. Findeisen (TU Darmstadt)

- Prof. Griehl (Köthen University of Applied Sciences)

- Prof. Sommer (Köthen University of Applied Sciences)

- Prof. Langer (Merseburg University of Applied Sciences)

Publications

[1] S. Duvigneau, R. Dürr, L. Carius, and A. Kienle. Hybrid cybernetic modeling of polyhydroxyalkanoate production in cupriavidus necator using fructose and acetate as substrates. In Proc. IFAC World Congress - Berlin, July 11-17, 2020. IFAC-PapersOnLine, Volume 53, Issue 2, Pages 16872-16877.

[2] S. Duvigneau, R. Dürr, L. Kranert, A. Wilisch-Neumann, L. Carius, R. Findeisen, and A. Kienle. Hybrid cybernetic modeling of the microbial production of polyhydroxyalkanoates using two carbon sources. Computer Aided Chem. Eng., 50:1969-1974, 2021.

[3] S. Duvigneau, R. Dürr, J. Behrens, and A. Kienle. Advanced kinetic modeling of bio-co-polymer poly(3-hydroxybutyrate-co-3-hydroxyvalerate) production using fructose and propionate as carbon sources. Processes, 9(8):1260, 2021.

[4] R. Dürr, S. Duvigneau, and A. Kienle. Microbial production of polyhydroxyalkanoates - Modeling of chain length distribution. Computer Aided Chem. Eng., 50:1975-1981, 2021.

[5] L. Carius, J. Pohlodek, B. Morabito, A. Franz, M. Mangold, R. Findeisen, and A. Kienle. Model-based state estimation utilizing a hybrid cybernetic model. In Proc. 10th IFAC Symposium on Advanced Control of Chemical Processes - ADCHEM 2018 - Shenyang, 25.-27. July, 2018. IFAC-PapersOnLine, Volume 51, Issue 18, 2018, Pages 197-202.

[6] B. Morabito, A. Kienle, R. Findeisen, and L. Carius. Multi-mode model predictive control and estimation for uncertain biotechnological processes. In Proc. 12th IFAC symposium on Dynamics and Control of Process Systems - DYCOPS 2019, Florianopolis/Brazil, 23-26 April, 2019. IFAC-PapersOnLine, Volume 52, Issue 1, Pages 709-714.

[R17] A. Franz, H.-S. Song, D. Ramkrishna, and A. Kienle. Experimental and theoretical analysis of poly(β-hydroxybutyrate) formation and consumption in ralstonia eutropha. Biochem. Engng. J., 55:49–58, 2011.

[R18] A. Franz, R. Rehner, A. Kienle, and H. Grammel. Rapid selection of glucose utilizing variants of ralstonia eutropha h16 by incubation with high substrate levels. Letters Appl. Microbio., 54:45–51, 2012.

[R19] K. Sudesh, H. Abe, and Y. Doi. Synthesis, structure and properties of polyhydroxyalkanoates: Biological polyesters. Prog. Polym. Sci., 25:1503–1555, 2000.