Process variants

Control and diagnosis of simulated moving bed chromatography

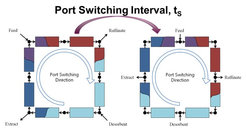

A Simulated moving bed (SMB) process that uses simulated counter-current movements of the solid and liquid phases was introduced in 1960s. The conventional four-zone SMB process forms a closed ring with several packed-bed columns. This ring is divided into four zones by two inlets (feed and desorbent) and two outlets (extract and raffinate). The positions of four ports are shifted to the same direction of the liquid phase flow to simulate the counter-current flow of the solid phase. A feed mixture continuously enters into the process through the feed port, and the solute-free solvent, usually the same solvent composition as feed, enters into the process through the desorbent port. The mixture components are separated in the chromatographic columns and collected at two outlets (raffinate: less-retained components, extract: more-retained components). Because of the periodic repetition of port switching, the SMB process does not reach the steady-state but cyclic steady-state (CSS). The cyclic repetition of the outlet profiles causes difficult monitoring of the process output. The most common method is collecting process outputs for one or several port switching intervals and analyzing them with external analysis unit, which provides delayed process output.

Splitting Ternary Mixtures - Double Layer Simulated Moving Bed Chromatography

To tackle challenging separation problems the PCF group has continued its activities dedicated to develop new types of chromatographic separation processes. The group’s main focus is on providing opportunities to split a feed stream continuously into three fractions. In such “center cut separations”, target components should be collected with a high level of purity in the second (middle) fraction. Thus, the generic chromatographic separation processes we are currently developing are considered to be very promising for selectively isolating any chosen target component present in a specific complex multi-component feed mixtures as generated by numerous processes.

Recently a new multi-column simulated moving bed (SMB) process concept was introduced capable to perform a continuous split of ternary feed mixtures. Considering an operational similarity between SMB chromatography and fractional distillation and mimicking the dividing wall distillation process, which is established and widely used for multi-component fractional distillation, a novel continuous SMB configuration was suggested [1]. This new concept can provide improved performance compared to alternative ternary separation SMB concepts (as SMB cascades and integrated 8-zone SMB).

The rational design of the sophisticated periodic chromatographic operation regime requires reliable knowledge regarding the underlying adsorption isotherms. These thermodynamic functions are specific for each chromatographic separation problem and depend on the mobile and stationary phases selected. To determine the coursed of competitive isotherms a novel experimental method was developed, which acquires and exploits additional information provided by the positions and heights of intermediate plateaus formed during breakthrough experiments (Figure left, [2]).

For the optimization of SMB processes a widely applicable numerical short-cut design tool was developed [3]. This tool can also incorporate unavoidable hold-up volumes caused by pipes and other extra-column dead volumes. The successful application to DL-SMB processes was recently reported [4] and forms a basis for currently carried out experimental investigations using a 12 column set-up.

![Illustration of ternary breakthrough experiments; principle of dividing-wall distillation and DL-SMB; illustration of the DL-SMB design diagram together with predicted internal concentration profiles for three component [1-4].](/4653979/original-1728654296.jpg?t=eyJ3aWR0aCI6MjQ2LCJvYmpfaWQiOjQ2NTM5Nzl9--834260aa7bb0da13f1080528672aabbf0916e2ca)

[1] Lee, J.W. (2021). Double-Layer Simulated Moving Bed Chromatography for Ternary Separations: Serialized Layer Configurations. Industrial and Engineering Chemistry Research, 60(24), 8911–8926. doi: 10.1021/acs.iecr.1c01268

[2] Zarei, S., Harriehausen. I., Lee, J. W. & Seidel-Morgenstern, A. (2024). Equilibrium loadings and adsorption isotherm model parameters estimated from multi-component breakthrough curves, Adsorption, 30, 2295-2312. doi: 10.1007/s10450-024-00549-5

[3] Lee J.W., Kienle A. & Seidel-Morgenstern A. (2021). Numerical Short-Cut Design of Simulated Moving Bed Chromatography for Multicomponent Nonlinear Adsorption Isotherms: Nonstoichiometric Langmuir Model. Industrial & Engineering Chemistry Research, 60, 10753-10763. doi: 10.1021/acs.iecr.1c00671

[4] Lee, J. W., Zarei, S., Kienle, A. & Seidel-Morgenstern, A. (2024). Short-cut design of double-layer simulated moving bed chromatography for continuous ternary mixture separation: Langmuir isotherms. Industrial & Engineering Chemistry Research, doi: 10.1021/acs.iecr.4c01531

Separation and racemization to obtain pure enantiomers

Enantiomers are pairs of chemical compounds, which behave as image and mirror-image. Since the living world constitutes exclusively of L-forms of amino acids, the two enantiomers generate different effects in biological systems. For this reason there is a need in efficient methods to provide pure enantiomers. Racemization using suitable enzymes (racemases) is a promising technology. Based on successfully immobilizing and testing mandelate and amino acid racemases the group developed in the last years combinations with enantioselective crystallization and chromatographic separation processes. Essential ingredient of the continuous processes investigated is the exploitation of racemization reactions carried out in enzymatic fixed bed reactors (EFBR) which contain immobilized racemases. Two of the principles investigated are illustrated in the figure.

We studied the continuous separation of racemic DL-methionine using Simulated Moving Bed (SMB) chromatography combined with an immobilized amino acid racemase (Figure, left, [1]). Subsequently, exploiting an amino acid racemase originating from Pseudomonas putida, D-methionine could be produced with very high purity and yield using the configuration shown in the figure (left).

An attractive example for bypassing equilibrium limitations was successfully investigated. It is based on accomplishing a complete chiral inversion of an amino acid and exploits two fluidized bed crystallizers applied for separating racemic mixtures of the amino acid asparagine monohydrate in water. The technology enables producing both enantiomer crystals simultaneously at high purity providing narrow crystal size distributions and significantly enhancing productivity (Figure, right, [2]).

![Left: Coupling of SMB chromatography with an enzymatic fixed bed reactor (EFBR) for racemization to continuously provide an enantiomer A from a racemic feed mixture (A+B) [1]. Right: Scheme of the pilot plant for experimental demonstration of continuous chiral inversion by coupling enzymatic racemization and 2-stage enantioselective fluidized bed crystallization [2].](/3592773/original-1728654296.jpg?t=eyJ3aWR0aCI6MjQ2LCJvYmpfaWQiOjM1OTI3NzN9--191f517968e9113c094a4d2d94a4d4e5323be6c7)

[1] Harriehausen I., Bollmann, J., Carneiro, T., Bettenbrock, K., & Seidel-Morgenstern, A. (2021). Characterization of an Immobilized Amino Acid Racemase for Potential Application in Enantioselective Chromatographic Resolution Processes, Catalysts, 11, 726. doi: 10.3390/catal11060726

[2] Gänsch, J., Oliynyk, K., Potharaju, S., Seidel-Morgenstern, A. & Lorenz, H. (2024). Continuous chiral inversion by coupling enzymatic racemization with enantioselective fluidized bed crystallization. Industrial & Engineering Chemistry Research, invited, accepted.

|

![Illustration of ternary breakthrough experiments; principle of dividing-wall distillation and DL-SMB; illustration of the DL-SMB design diagram together with predicted internal concentration profiles for three component [1-4]. Illustration of ternary breakthrough experiments; principle of dividing-wall distillation and DL-SMB; illustration of the DL-SMB design diagram together with predicted internal concentration profiles for three component [1-4].](/4653979/original-1728654296.jpg?t=eyJ3aWR0aCI6ODQ4LCJmaWxlX2V4dGVuc2lvbiI6ImpwZyIsIm9ial9pZCI6NDY1Mzk3OX0%3D--f80c3a7b0b39570f48285295b52c7b74d58cf3a1)

![Left: Coupling of SMB chromatography with an enzymatic fixed bed reactor (EFBR) for racemization to continuously provide an enantiomer A from a racemic feed mixture (A+B) [1]. Right: Scheme of the pilot plant for experimental demonstration of continuous chiral inversion by coupling enzymatic racemization and 2-stage enantioselective fluidized bed crystallization [2]. Left: Coupling of SMB chromatography with an enzymatic fixed bed reactor (EFBR) for racemization to continuously provide an enantiomer A from a racemic feed mixture (A+B) [1]. Right: Scheme of the pilot plant for experimental demonstration of continuous chiral inversion by coupling enzymatic racemization and 2-stage enantioselective fluidized bed crystallization [2].](/3592773/original-1728654296.jpg?t=eyJ3aWR0aCI6ODQ4LCJmaWxlX2V4dGVuc2lvbiI6ImpwZyIsIm9ial9pZCI6MzU5Mjc3M30%3D--8282e74ffa2e305925f66175dc8d6466104d3b02)