Selective Crystallization

Crystallization processes play a role in many industries, and are applied for manufacture of commodities (e.g. inorganic salts) and fine chemicals, as pharmaceuticals, food and agrochemicals. The two general objectives of crystallization processes are, first, separation and purification of substances, and, second, production of particles of desired properties, as for example a definite particle size distribution. Often both objectives are combined and the crystallization step within the industrial (synthesis – separation –formulation) process chain has to fulfill several tasks simultaneously.

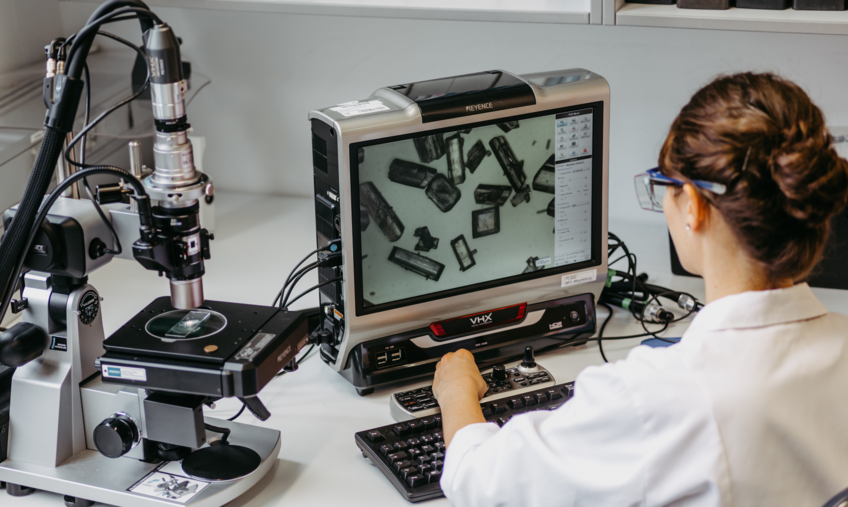

On that basis the goal of the projects in the crystallization team are directed to deeper understand, design and optimize crystallization-based processes aiming to isolate pure target compounds from mixtures while keeping control of the particulate properties of the compounds as well. Those mixtures might be composed of only two very similar components, as enantiomers in a racemic mixture, or contain a multitude of constituents, as it is the case in plant extracts or synthesis mixtures (Figure 1).

To address such separation tasks the underlying phase equilibria (solid-liquid as well as solid-solid and liquid-liquid equilibria (SLE, SSE, LLE)) and crystallization kinetics need to be determined. Based on this key information, separation processes are derived and their applicability and performance verified. In the work we focus on developing novel and advanced variants of separation processes that facilitate to produce pure compounds at desired target properties as well as process characteristics (yield, productivity). During the last couple of years beside batch process concepts continuous process concepts were studied to a greater extent. Model and industrially-relevant example systems investigated ranged from enantiomers, over synthesis-mixtures to the isolation of plant-based pharmaceutical compounds from extracts and particulate lignin from wood-based black liquors.

Various batchwise and continuously operated crystallization facilities from a couple of mL’s up to 20 L reactor volume are applied. The reactors can be equipped with various in- and online measurement techniques to follow separation progress and particle evolution by analyzing temperature, solution concentration (supersaturation), enantiomeric excess, particle size etc. Reactor operation and data acquisition are supported using a process control system.

Selected topics will be described in more detail in the following:

- Thermodynamics and crystallization kinetics

- Process design

- Natural products.

These tasks are handled interdisciplinary in different research groups of the Max Planck Institute and in cooperation with companies and universities.